This article covers common DIY basics, so I don’t have to explain them in every tutorial! If you have questions about any steps shown in any tutorial on this site, leave a comment so I can explain further.

Getting things square.

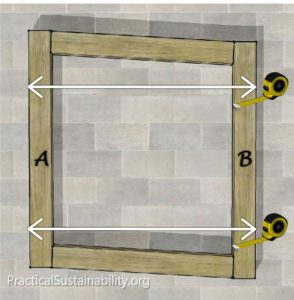

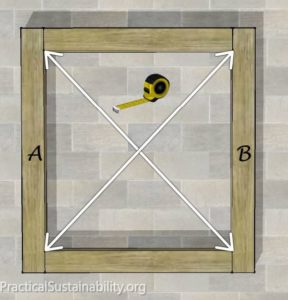

Don’t own a large builders square? You’ll need to square up your timber using a measuring tape.

Method 1 – squaring a frame.

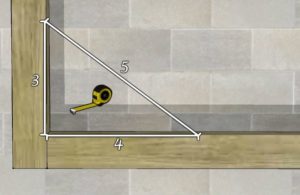

Method 2 – squaring A corner.

You can easily use mathematics to get something square! Pythagorean theorem tells us that in a right angled triangle, A² + B² = C².

By marking a line on one timber at 3, and on the other at 4 – measured out from the corner – you can wiggle your timbers around until the diagonal measurement equals 5. Your joint is now square!

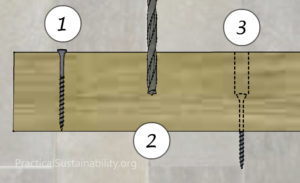

“Lengthen” your screws.

Large screws can be expensive, and it’s not really worth buying a huge box if you only need them for a few joints. Using this method can save you time and money. Make sure that when you oil or paint your timber you get some inside the screw hole shown in (3), or it will reduce the life-span of your project.

Pilot holes.

When screwing into thin or delicate timbers, it is always recommended that you first drill a pilot hole. Basically they make room for the core of the screw so that it doesn’t squeeze your timber apart as it goes in – which will prevent splitting. The screw thread is wider than the hole and still grips the timber properly.

COMING SOON! I’ll add the rest of these tips as required by new tutorials. – Chris 28/1/17

Measuring and cutting square ends.

Drilling various size holes into plastic with one drill bit.

Counter-sinking.

Blunt your nails to avoid splitting timber.

Disassembling pallets.

3 thoughts on “DIY basics tips”